Titanic Connection

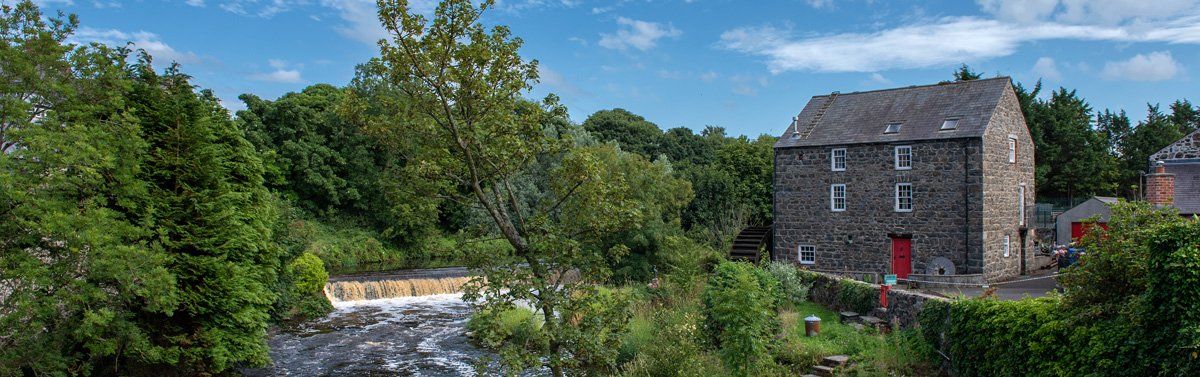

William Anderson established a spade mill in Bushmills in the early 1800s, we have no records of the exact date but it was operating in 1820. The spade mill continued to operate until 1916, the 'ironworks' which was located here are described on a late 19th century maps as being a “foundry”. During the peak of its operations, it may have been driven by two water wheels on the race from the river Bush to work the trip hammer and bellows. Nothing remains of this today apart from some outbuilding and the front wall adjacent to Woodville House. The spade mill produced a whole range of spades and agricultural implements, the product was of high quality and became well known throughout Ireland and certainly an equal to the Patterson Spade Mill, there is evidence of a close connection between the two foundries.

The spade mill was not a simple business, in Ireland there were more than 150 different kinds of spades which varied from area to area and for different purposes. A spade of quality had to last for more than one generation and able to be used with bare feet. To operate a Spade Mill needed not only hand skills but knowledge of water wheels and their workings. The developments that started at the spade mill here in Bushmills would eventually reach around the world and connect to many icons including the Titanic, Bentley cars and the Sopwith Camel: - The story starts in 1823 when William Anderson employed a young 21 year journeyman and spade maker from Londonderry called John Gwynne.

John was ambitious and hard-working, he also was amorous and took a liking to William Anderson's sixteen-year-old daughter Agnes, the pair ran off to Liverpool together which cause a scandal in the village. William had a brother Henry, a cotton importer who lived in Liverpool and he tracked the couple down, persuaded them to get married and return to Bushmills as a respectable married couple, which they did. William Anderson's sons were involved in other businesses, so when he was ready to retire the Spade Mill was handed over to John and Agnes who kept the business running. They managed to secured contracts to supply spades and implements for work on the Victoria Channel when it was being created to improve Belfast harbour.

During the Great Famine, they supplied spades and agricultural implements for public works which included land reclamation from bog land and fens. It was this focus on drainage of waterlogged areas and the reclamation of bog land that led John Gwynne to look at the possibilities for drainage pumps. Agnes had another uncle in New Orleans who bought and shipped cotton to her uncle Henry in Liverpool, it was through this connection that the Gwynne's secured the patent rights for the British Empire of the American Centrifugal Pump which had been patented in 1815. This was a major step forward in their business and in 1851 they demonstrated the new centrifugal pump at the Great Exhibition in London where it powered the grand water feature.

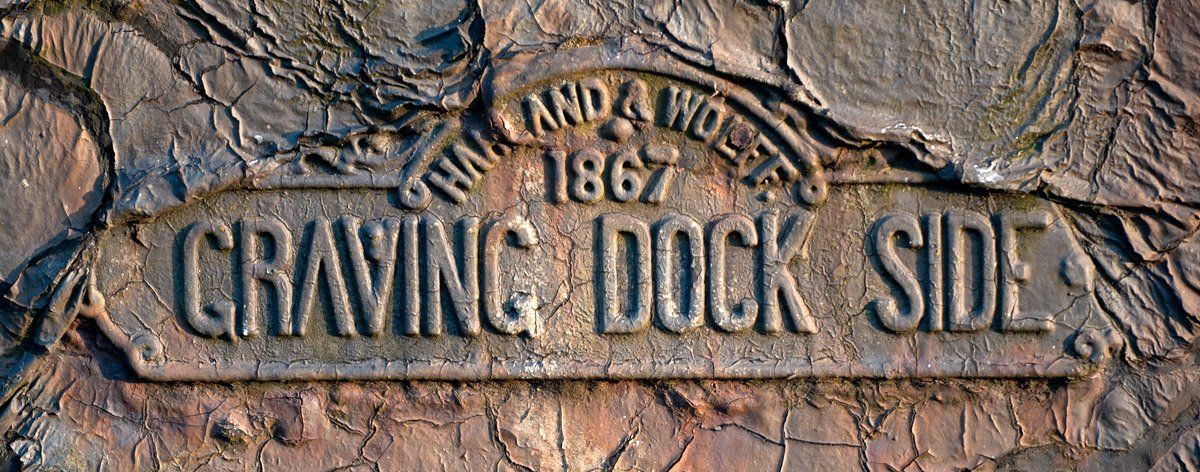

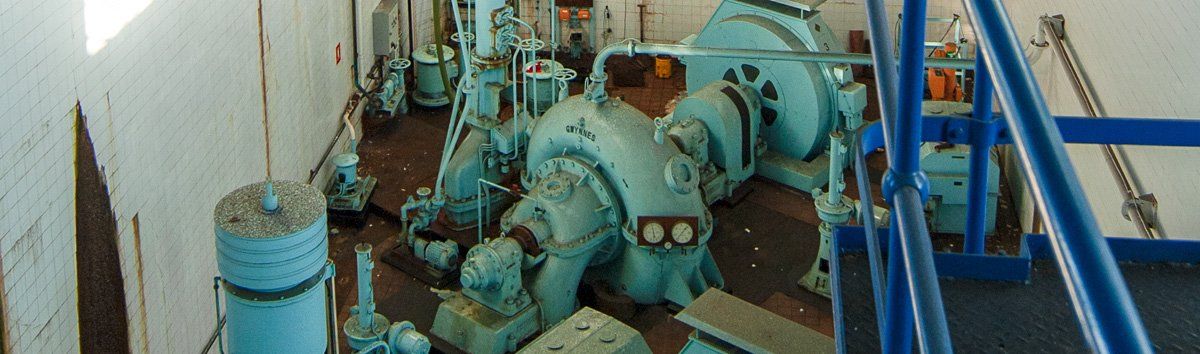

Up to this time the couple resided in Bushmills and raised five sons here, but in 1850 due to business expansion, they decided to move to London and form the Gwynne Engineering Company. Over the next decade, their pumps and pumping engines would become known worldwide. You can see examples of the Gwynne pump if you visit the Thompson Pump House and Dock in Belfast, where the Titanic, Olympic and Brittanic were fitted out along with many other famous Harland & Wolff ships. The pumps installed in the Thompson Pump House could empty 21 million gallons of water in 90 minutes and were the most powerful marine pumps of their day.

The Gwynne Engineering Company went on to manufacturer the Albert car and eventually they produced their own car called the Gwynne 8. They also produced fire engines which carried their water pumps onboard. One was made for the Marconi Factory and is now on exhibition in the Coventry Museum of Transport. During the First World War the company manufactured under license, the 130hp French Clerget 9B Rotary Engine which powered the Sopwith Camel fighter plane that served on the Western Front. During this time a young engineer Lieutenant W.O.Bentley was assigned to the company by the admiralty. He was to work on improvements to the Clerget engine.

His improvements included a dual ignition system and revision of the cylinders which led to the modified engine producing 150hp. The French company refused to accept the new modification to their engine, the admiralty then had the engine manufactured in England. The new engine became known as the BR 1 (Bentley Rotary) and would power the next generation of Sopwith Camels. Bentley later formed the Bentley Motor Company which is still in existence today with a factory in Cheshire, Bentley was always seen as a rival to Rolls Royce.